Why Choosing the Right Hardwood Flooring Manufacturer Matters

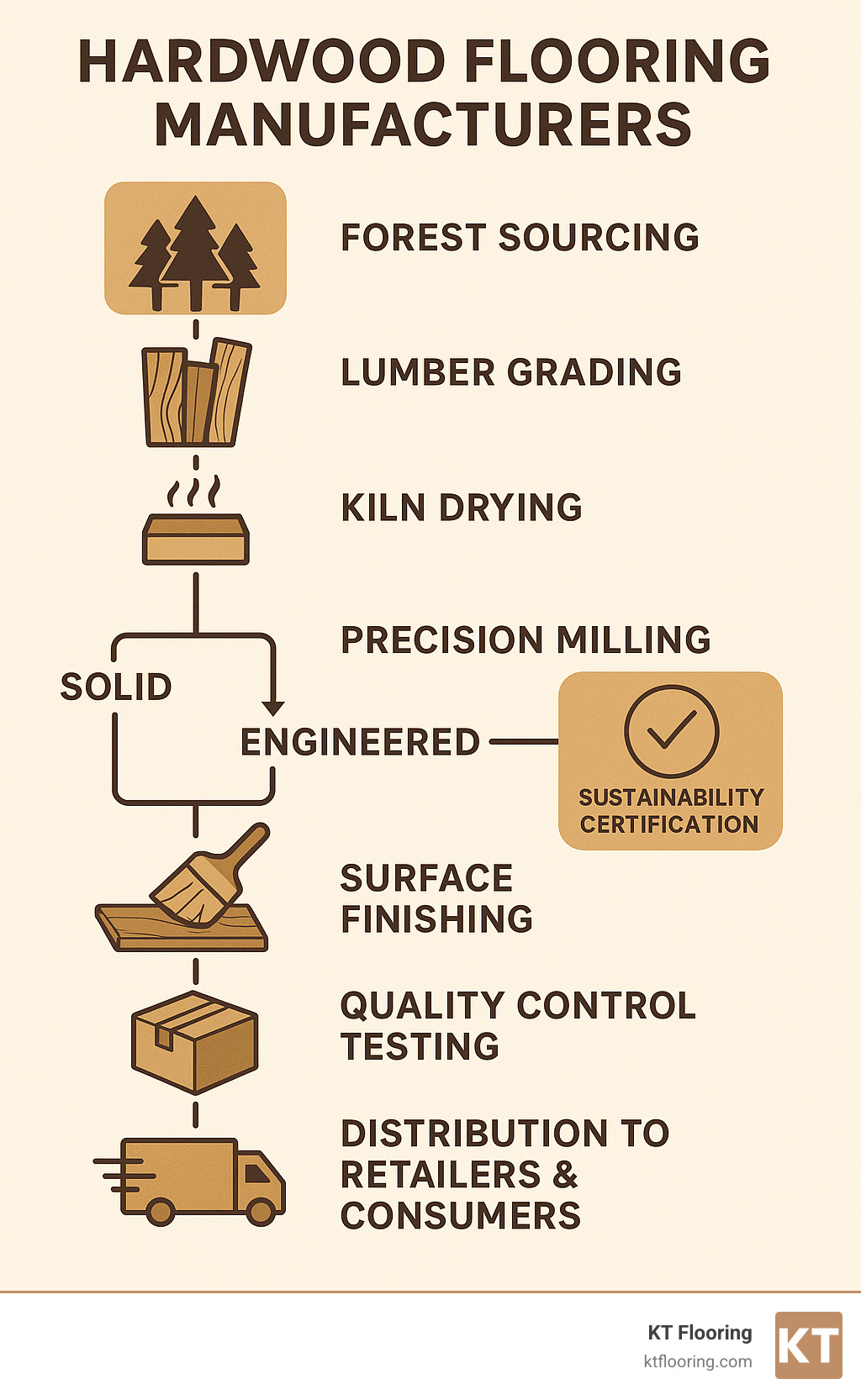

Hardwood flooring manufacturers shape every aspect of your floor’s quality, durability, and long-term value. Here are the key factors that separate leading manufacturers from the rest:

Top U.S. Hardwood Flooring Manufacturers:

– Bruce – 140+ years experience, 200+ solid hardwood styles, lifetime warranties

– Shaw Floors – Engineered hardwood specialist, waterproof options, wide distribution

– Mullican – NWFA certified, 50-year finish warranties, sustainable Appalachian lumber

– Somerset – Vertically integrated production, millions of board feet processed annually

– Carlisle Wide Plank – Premium custom floors starting at $12+ per square foot

What Makes Manufacturers Different:

– Quality certifications (NWFA/NOFMA, FloorScore, FSC)

– Wood species selection (90% domestic oak, maple, hickory)

– Construction type (solid vs. engineered hardwood)

– Warranty coverage (25-year to lifetime options)

– Price ranges ($3-$30+ per square foot based on internet averages)

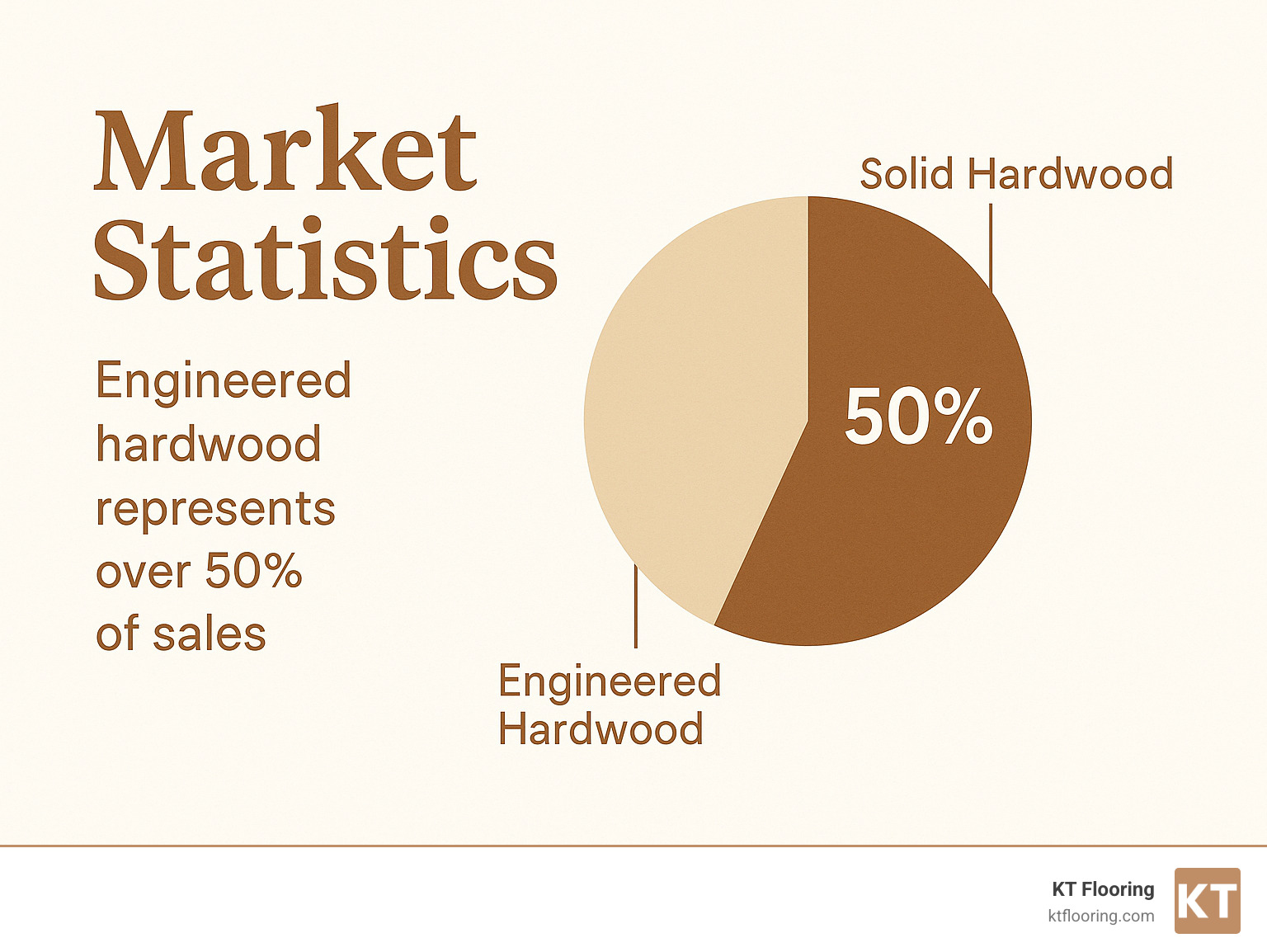

The U.S. hardwood flooring market is valued at over $4 billion annually, with engineered hardwood now representing more than 50% of all sales. This shift reflects homeowners’ growing demand for moisture-resistant options and easier installation methods.

Key trends driving manufacturer innovation include:

- Wide plank flooring (5+ inches) now accounts for 30% of installations

- Sustainable sourcing with FSC certification becoming standard

- Pet-proof and waterproof technologies for active households

- Direct-to-consumer models reducing costs by eliminating middlemen

As someone who’s worked with hardwood flooring manufacturers for over 50 years at KT Flooring, I’ve seen how the right manufacturer choice can make or break a flooring project. The partnerships we’ve built with leading manufacturers ensure our New Hampshire and Northeast Massachusetts customers get both quality products and reliable warranties.

Learn more about hardwood flooring manufacturers:

– Best laminate flooring brands

– Best flooring for kitchens

– Best flooring for basements

Why Compare Hardwood Flooring Options?

Making the right choice in hardwood flooring manufacturers gives you decision confidence that lasts decades. When we meet with homeowners during our free in-home consultations across New Hampshire and Northeast Massachusetts, we often see the consequences of hasty manufacturer decisions – floors that warp, finishes that wear prematurely, or warranties that don’t cover real-world use.

The long-term ROI of choosing quality manufacturers is substantial. While premium hardwood may cost more upfront, manufacturers with proven track records deliver floors that can be refinished multiple times, potentially lasting several decades. This longevity often makes quality hardwood more economical than cheaper alternatives that need replacement every 10-15 years.

Snapshot of Today’s Hardwood Market

Walking into the hardwood flooring market today feels like stepping into a completely different world than it was just ten years ago. The biggest shift? Engineered hardwood now outsells solid hardwood, claiming over 50% of all hardwood flooring sales across the United States. This isn’t just a trend – it’s a fundamental change in how homeowners think about their floors.

What’s driving this change? Modern living demands more from our floors. Families want the beauty of real wood but need it to handle moisture from busy kitchens, pet accidents, and basement installations where solid hardwood simply can’t go. Hardwood flooring manufacturers have responded by perfecting engineered construction that delivers wood’s natural beauty with improved durability.

The wide-plank revolution tells another fascinating story. Planks measuring 5 inches or wider now account for over 30% of new installations. Homeowners are moving away from the narrow strips of previous decades, embracing broader planks that make rooms feel more spacious and showcase wood’s natural character.

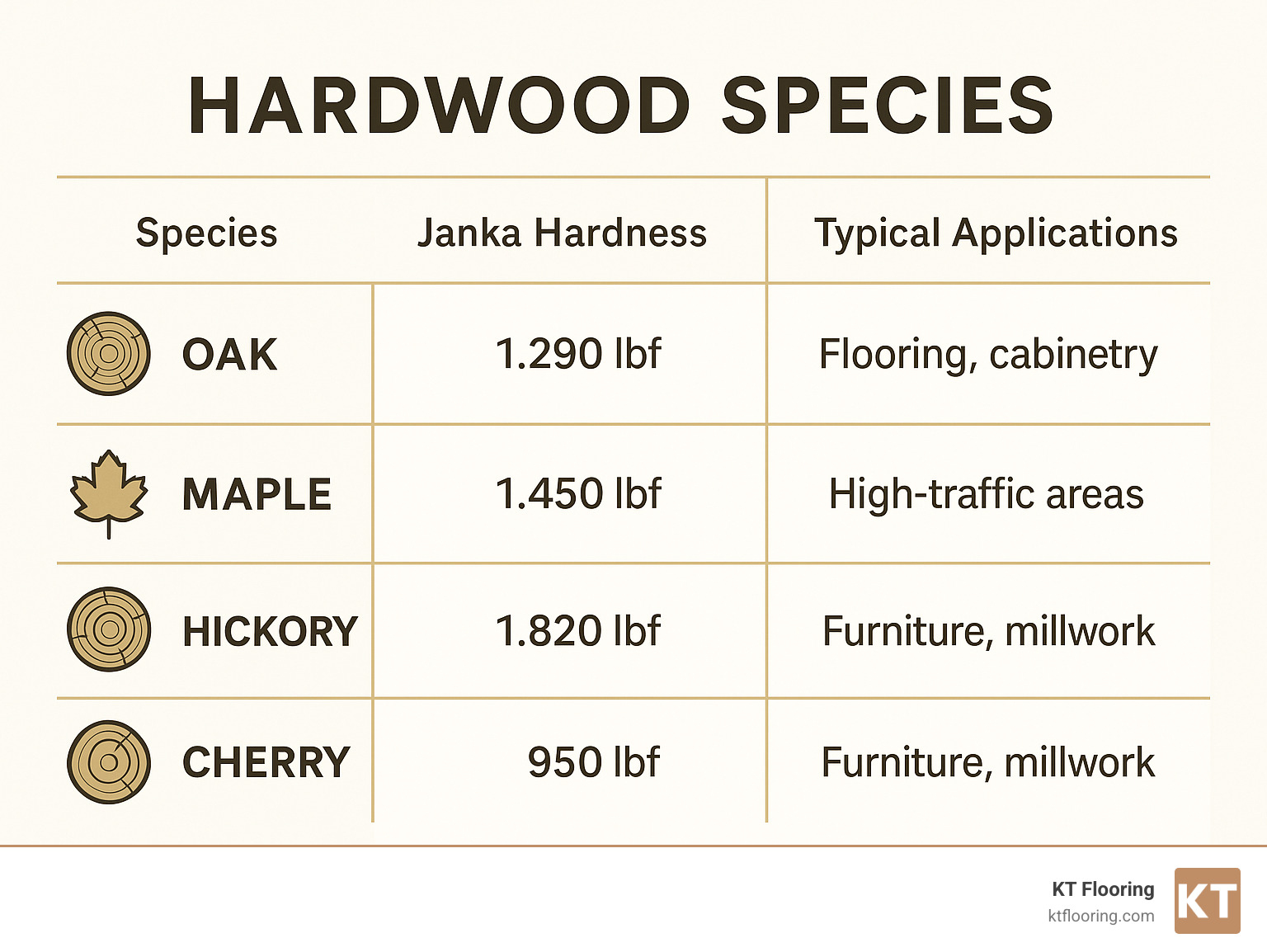

American wood species remain king, with over 90% of hardwood flooring sold domestically coming from familiar favorites like oak, maple, and hickory. These domestic species offer the perfect combination of durability, consistent availability, and the grain patterns that feel like home to American families.

Let’s talk numbers that matter to your wallet. Quality hardwood flooring spans an impressive price range from $3 to $30+ per square foot based on internet data (these are market averages, not KT Flooring pricing). The variation reflects everything from basic builder-grade options to premium custom installations with hand-selected boards and artisan finishes.

NWFA and NOFMA standards provide the quality backbone of the industry. When manufacturers earn these certifications, they’re committing to strict production standards that protect your investment. Currently, over 25 certified manufacturers produce unfinished solid hardwood in the U.S., ensuring consistent quality across the market.

| Feature | Solid Hardwood | Engineered Hardwood |

|---|---|---|

| Construction | Single piece of wood | Multi-layer with hardwood veneer |

| Refinishing | Multiple times (5-7+) | Limited (1-3 times) |

| Moisture Resistance | Lower | Higher |

| Installation | Nail-down only | Nail, glue, or float |

| Subfloor Options | Wood only | Concrete and wood |

| Price Range | $3-$10/sq ft | $4.50-$8/sq ft |

Note: Prices shown are internet averages and not KT Flooring pricing

After five decades in this business, I’ve watched these market shifts at KT Flooring. The manufacturers who’ve thrived are those who listened to what families actually need – not just what looks good in a showroom, but what performs beautifully in real homes with real life happening on top of it.

What Sets Leading Hardwood Flooring Apart in 2025

The best hardwood flooring manufacturers in 2025 distinguish themselves through unwavering durability focus. Leading brands now offer planks with 3/4″ thickness, allowing for multiple refinishes and lifespans measured in decades rather than years.

Eco-friendly product lines have moved from niche offerings to mainstream expectations. FloorScore and FSC certifications are now standard among top manufacturers, with many going beyond basic compliance to achieve carbon-neutral production.

Customization depth separates premium manufacturers from mass-market producers. The best manufacturers offer extensive options for plank width, surface textures, stain colors, and finish types. Some even provide fully custom services, creating unique floors custom to specific architectural requirements.

Premium warranties reflect manufacturer confidence in their products. While basic warranties might cover 10-15 years, leading manufacturers offer 25-year, 50-year, or even lifetime warranties on their premium collections.

Heritage & Innovation in Hardwood Flooring

Legacy craftsmanship forms the foundation of the best hardwood flooring manufacturers. Companies like Bruce, with 140 years of experience, have perfected traditional techniques while embracing modern innovations. This combination produces floors that honor woodworking traditions while meeting today’s performance demands.

Advanced finishes represent one of the most significant innovations in recent years. Modern polyurethane formulations provide scratch resistance that would have been impossible decades ago. Some manufacturers now offer finishes that can withstand pet claws, high heels, and furniture dragging without showing visible wear.

Pet-proof and water-resistant technologies address real-world challenges. Bruce’s Dogwood® Densified Hardwood Flooring exemplifies this trend, offering “virtually pet proof” performance through advanced densification processes.

Popular species selection reflects both tradition and innovation. Oak remains the most popular choice, available in both red and white varieties, but manufacturers are expanding offerings to include hickory for its exceptional hardness, maple for its clean grain patterns, and exotic species for unique aesthetics.

Style & Technology

Wide plank options have become a defining feature of contemporary hardwood flooring. Manufacturers now regularly offer planks 5, 7, or even 9 inches wide, creating dramatic visual impact in modern spaces.

Scratch-resistant finishes incorporate advanced chemistry to maintain appearance despite daily wear. These finishes often include aluminum oxide particles that create surfaces significantly more durable than traditional polyurethane alone.

FloorScore certification ensures low VOC emissions, addressing growing health consciousness among consumers. This certification has become standard among quality manufacturers.

Quality Sourcing & Manufacturing

Appalachian and domestic lumber sourcing provides the foundation for America’s best hardwood floors. Somerset processes millions of board feet of premium Appalachian lumber annually, maintaining control over every step from lumber grading through finishing.

Engineered advancements have revolutionized hardwood manufacturing. Modern engineered hardwood typically comprises five to seven layers of plywood in its core, providing superior dimensional stability compared to solid wood.

NWFA certified manufacturers maintain industry-leading standards. The National Wood Flooring Association certification ensures manufacturers adhere to strict quality protocols, from raw material selection through final finishing.

European & Global Inspiration

Multi-layer construction techniques pioneered in Europe have influenced American manufacturing. European manufacturers developed sophisticated engineered construction methods that American companies have adapted and refined.

FSC options reflect European leadership in sustainable forestry. The Forest Stewardship Council certification has become increasingly important in the American market as consumers become more environmentally conscious.

Hand-Crafted & Custom Looks

Hand-scraped and wire-brushed finishes add character and texture to modern hardwood floors. These techniques create consistent results while maintaining the authentic appearance of traditional craftsmanship.

Reclaimed and rustic styles satisfy demand for floors with history and character. Manufacturers source reclaimed wood from old barns and factories, creating floors with unique patina impossible to achieve with new lumber.

Eco Leadership

Zero-waste initiatives demonstrate manufacturer commitment to environmental responsibility. Leading companies implement closed-loop manufacturing processes where sawdust becomes biomass fuel and wood chips become paper products.

Tree planting programs offset manufacturing environmental impact. Some manufacturers plant multiple trees for every tree harvested, creating net positive environmental impact over time.

Luxury & Bespoke Options

Fully custom widths and finishes represent the pinnacle of hardwood manufacturing. Companies like Carlisle Wide Plank Floors offer completely customized solutions, creating floors that are truly one-of-a-kind.

Premium price points starting at $12+ per square foot (based on internet averages, not KT Flooring pricing) reflect the extensive labor and materials required for bespoke manufacturing.

Value & Performance

Waterproof core options address moisture concerns without sacrificing hardwood aesthetics. Manufacturers like Proximity Mills offer engineered hardwood with waterproof cores that provide up to 72 hours of moisture protection.

Direct-to-consumer savings eliminate middleman markups, making quality hardwood more accessible while maintaining quality standards.

How to Compare Hardwood Flooring Like a Pro

After five decades of helping homeowners choose the perfect floors, I’ve learned that comparing hardwood flooring manufacturers like a pro comes down to knowing what questions to ask. The difference between a floor you’ll love for 30 years and one that disappoints you in five often lies in the details most people overlook.

Understanding price ranges helps you set realistic expectations from the start. Based on internet averages (not KT Flooring pricing), quality hardwood flooring spans from $3 to $30+ per square foot. Entry-level engineered options might start around $3-4 per square foot, while premium solid hardwood can reach $12-15 per square foot, and fully custom options can exceed $30 per square foot. These wide ranges reflect significant differences in species, grade, and manufacturing quality.

Warranty length tells you how much confidence a manufacturer has in their product. But here’s the insider tip – don’t just look at the years. Read what’s actually covered. Some manufacturers offer separate warranties for structural integrity, finish durability, and installation defects. The best warranties provide comprehensive coverage for 25-50 years or even lifetime protection on structural components.

Janka hardness ratings help you match wood species to your lifestyle. This scale measures how resistant wood is to denting and wear. Red oak sits at 1,290 pounds-force and serves as the industry benchmark. If you have active kids or pets, consider hickory at 1,820 pounds-force for superior durability. Maple offers a sweet spot at 1,450 pounds-force, providing excellent hardness with beautiful, clean grain patterns.

Certification standards separate legitimate manufacturers from those cutting corners. Look for NWFA/NOFMA certification for industry quality standards, FloorScore certification for low VOC emissions that protect your family’s health, and FSC certification for responsible forest management. CARB II compliance ensures California’s strict air quality standards, while Lacey Act compliance verifies legal timber sourcing.

Species selection should balance your aesthetic dreams with practical needs. Oak remains America’s favorite because it offers attractive grain patterns, good hardness, and consistent availability. Maple appeals to homeowners who prefer cleaner, more uniform grain patterns that work beautifully in contemporary designs. Hickory delivers exceptional durability for busy households but comes with more dramatic grain variation that isn’t everyone’s cup of tea.

Customization depth varies dramatically between manufacturers. Premium hardwood flooring manufacturers offer extensive plank width options from traditional 2.25 inches up to dramatic 7+ inch wide planks. Grade selection ranges from select grade for uniform, consistent appearance to rustic grades that accept natural character marks and color variation. Finish options typically include matte, satin, semi-gloss, or high-gloss, each creating different visual effects in your space.

Installation support can make or break your project experience. Some manufacturers provide detailed installation guides, professional training programs, and technical support hotlines. Others require certified installers for warranty coverage. At KT Flooring, our 50+ years of manufacturer relationships ensure we understand each brand’s specific installation requirements and warranty terms.

The smart approach combines all these factors rather than focusing on just one. A manufacturer offering rock-bottom prices with a 5-year warranty probably isn’t using the same quality materials as one offering 50-year coverage at a higher price point.

For detailed information about professional installation practices, visit our Engineered Hardwood Floors Installation page.

Eco-Friendly & Tech-Forward Trends

The hardwood flooring manufacturers leading the charge in 2025 are embracing environmental responsibility like never before. What started as a nice-to-have feature has become an essential part of quality manufacturing, and honestly, it’s about time.

Low-VOC finishes have transformed from specialty products to industry standards. These advanced formulations dramatically reduce indoor air pollution while maintaining the durability we expect from quality hardwood. FloorScore-certified products now emit minimal volatile organic compounds, which means you can install beautiful hardwood without worrying about your family breathing in harmful chemicals for months afterward.

The beauty of reclaimed and thermal-treated lumber lies in its double benefit – environmental responsibility meets stunning aesthetics. Reclaimed wood prevents perfectly good lumber from ending up in landfills while giving you floors with character that’s impossible to replicate with new materials. Those nail holes, weathered grain patterns, and subtle color variations tell stories that new lumber simply can’t match.

Thermal treatment represents another leap forward in sustainable manufacturing. This chemical-free process modifies wood properties by using controlled heat, improving stability while creating distinctive color variations naturally. It’s fascinating how manufacturers can improve wood performance without adding any synthetic chemicals.

Waterproof wood technologies have revolutionized where we can install hardwood flooring. Bruce’s waterproof wood flooring allows installation in bathrooms, laundry rooms, and basements – spaces where traditional hardwood would buckle and warp within months. For the latest research on waterproof flooring, visit Bruce’s waterproof wood flooring guide.

Densified layers showcase how manufacturers are pushing the boundaries of wood performance. This process compresses wood fibers to increase density and hardness, creating floors that resist denting and wear far better than traditional hardwood. Bruce’s Dogwood® Densified Hardwood exemplifies this technology, offering “virtually pet proof” performance that would have been impossible just a decade ago.

Radiant-heat compatibility opens up installation possibilities that make winter mornings much more pleasant. Engineered hardwood’s dimensional stability makes it perfect for installation over radiant heating systems. There’s something wonderful about the combination of gentle warmth rising through beautiful natural wood – it’s comfort and elegance working together.

Carbon-smart sourcing addresses the bigger picture of climate responsibility. Leading manufacturers now implement carbon-neutral or even carbon-negative practices through efficient transportation, renewable energy use, and forest management that actually sequesters more carbon than it releases. It’s encouraging to see an industry that depends on trees taking the lead in protecting forests.

Digital room visualizers might seem like a small innovation, but they’re game-changers for homeowner confidence. These tools let you see exactly how different hardwood options will look in your actual space, reducing the guesswork that used to make flooring decisions so stressful. After 50 years of helping customers at KT Flooring, I can tell you that anything that helps homeowners visualize their final result leads to much happier customers.

Frequently Asked Questions about Hardwood Flooring

After working with hardwood flooring manufacturers for over 50 years at KT Flooring, we’ve heard just about every question homeowners have about hardwood floors. Here are the answers to the three questions that come up most often during our free in-home consultations across New Hampshire and Northeast Massachusetts.

How do solid and engineered hardwood warranties differ?

The warranty differences between solid and engineered hardwood can be confusing, but understanding them helps you make a smarter investment decision.

Solid hardwood warranties are usually straightforward – most quality manufacturers offer lifetime structural warranties because solid wood, when properly maintained, can last for generations. The wood itself rarely fails. However, finish warranties on solid hardwood are typically shorter, ranging from 10 to 25 years, because you can always sand and refinish solid hardwood to restore its original beauty.

Engineered hardwood warranties are more complex due to their multi-layer construction. The structural warranty covers the engineered core and typically lasts 25 to 50 years. But here’s where it gets interesting – the veneer layer warranty depends on thickness. Thicker veneer layers (4mm or more) often come with longer finish warranties because they can be refinished once or twice. Thinner veneers (2mm or less) usually cannot be refinished, so their finish warranty is essentially their total lifespan warranty.

Installation warranties matter for both types, and this is where things can get tricky. Some hardwood flooring manufacturers will void their warranty if installation doesn’t meet their exact specifications. Others provide comprehensive coverage regardless of who installs the floor. At KT Flooring, we make sure every installation meets manufacturer requirements, protecting your warranty investment.

Which certifications guarantee responsible wood sourcing?

With growing environmental awareness, more homeowners want to know their beautiful hardwood floors didn’t contribute to deforestation or illegal logging. Several certifications help guarantee responsible sourcing, though they vary in strictness.

FSC (Forest Stewardship Council) certification provides the gold standard for responsible forestry. FSC-certified wood comes from forests managed according to strict environmental, social, and economic standards. This includes protecting biodiversity, respecting indigenous rights, and maintaining forest health for future generations. When you see FSC certification from hardwood flooring manufacturers, you can feel confident about your environmental impact.

PEFC (Programme for the Endorsement of Forest Certification) offers another internationally recognized system. While less rigorous than FSC, PEFC certification still ensures basic sustainable practices and legal compliance across global supply chains.

Lacey Act compliance might sound technical, but it’s crucial for preventing illegal timber from entering the U.S. market. This law requires documentation proving legal harvest and transport, helping protect forests worldwide and supporting legitimate forestry operations.

SFI (Sustainable Forestry Initiative) focuses specifically on North American forests, emphasizing science-based management, wildlife habitat protection, and soil and water conservation. Many domestic manufacturers carry SFI certification alongside other credentials.

Is buying hardwood online riskier than in-store?

Online hardwood shopping has definitely improved over the years, but it’s not without risks and benefits worth considering.

The advantages of online shopping include access to wider selections, easy price comparisons, and detailed customer reviews that help you learn from other homeowners’ experiences. Many online retailers now offer high-resolution images, detailed specifications, and sample programs that let you see and feel the actual flooring before committing to a full purchase.

The risks are real though. You can’t physically examine the flooring quality, and colors often look different on computer screens than in your actual lighting conditions. Installation support may be limited, and if problems arise, getting warranty service from a distant company can be frustrating and slow.

The key to successful online purchases is choosing reputable hardwood flooring manufacturers and retailers with strong customer service records. Look for companies offering free or low-cost samples, clear return policies, installation guidance, responsive customer service, and straightforward warranty terms.

At KT Flooring, we’ve found that combining online research with in-person expertise works best for our customers. We leverage our manufacturer relationships to provide competitive pricing while offering face-to-face consultations, professional installation, and local warranty service. When something goes wrong – and occasionally it does even with the best products – you’ll have a local team that knows your project and stands behind the work.

After five decades in this business, we’ve learned that the right hardwood flooring manufacturers combined with proper installation and local service support creates the best outcome for homeowners. It’s not just about getting a good deal – it’s about getting floors that will look beautiful and perform well for decades to come.

Conclusion

After exploring today’s leading hardwood flooring manufacturers, one thing becomes crystal clear: the right choice transforms your home for decades to come. We’ve seen this over our 50+ years at KT Flooring, watching families enjoy beautiful floors that still look stunning after their kids grow up and move out.

The manufacturers we’ve discussed each bring something special to the table. Some excel at traditional craftsmanship, others push the boundaries with waterproof technologies, and many lead the charge in sustainable practices. What they all share is a commitment to quality that shows in every plank.

The KT Flooring advantage comes from knowing these manufacturers inside and out. We’ve worked with them through product launches, warranty claims, and everything in between. When a manufacturer says their finish will last 25 years, we know whether that’s realistic or just marketing fluff. This knowledge protects our customers from disappointment down the road.

Our free in-home consultations take the guesswork out of choosing hardwood flooring manufacturers. Instead of staring at tiny samples under fluorescent store lights, we bring full-size samples to your home. You can see how different manufacturers’ products look with your actual lighting, furniture, and décor. It’s amazing how different a floor can look in your living room versus a showroom.

Our 50 years of expertise means we’ve seen manufacturing trends come and go. We remember when engineered hardwood was new and untested. Now it’s proven technology that solves real problems for homeowners. We’ve also seen manufacturers make bold claims that didn’t pan out, which helps us steer customers toward proven performers.

The relationships we’ve built with top manufacturers benefit every customer who walks through our doors. When you need warranty service or have installation questions, our established partnerships ensure you get answers quickly. We’re not just another dealer to these manufacturers – we’re long-term partners who’ve earned their respect and support.

Living in New Hampshire and Northeast Massachusetts means dealing with real seasonal changes that test flooring materials. The manufacturers we recommend have proven themselves in our climate, from humid summers to dry winters with heating systems running full blast.

The hardwood industry keeps evolving, and that’s exciting. New finishes resist scratches better than ever. Waterproof cores let you put real hardwood in places that were off-limits before. Sustainable practices mean beautiful floors don’t come at the environment’s expense.

Ready to find which hardwood flooring manufacturers are perfect for your project? Visit our Flooring Brands page to explore our manufacturer partnerships, or contact us for your free consultation. We’ll help you steer the options and find a floor that makes you smile every time you walk through your door.